Sheet metal processing industry

Provide professional solutions for the sheet metal processing industry

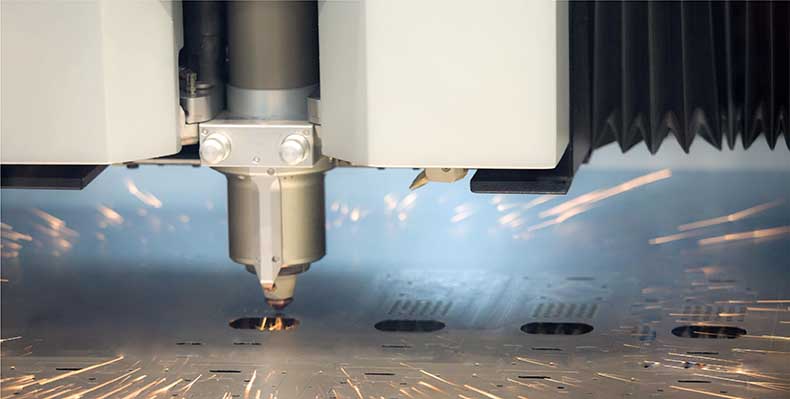

Laser cutting technology and laser cutting machine equipment are being familiar and accepted by the majority of board processing companies,And with its high processing efficiency、High processing accuracy、Good quality of cutting section、It can perform three-dimensional cutting processing and many other advantages gradually replace traditional sheet metal cutting equipment(Mainly CNC equipment,Including scissors、punch、Flame cutting、Plasma cutting、Traditional plate processing equipment such as high pressure water cutting)。Laser processing technology plays an important role in sheet metal processing technology,Improves labor productivity of sheet metal technology,Promote the development of sheet metal technology。High flexibility of laser cutting machine,Can greatly reduce the processing cycle,Fast cutting speed,High production efficiency,Improve processing accuracy,Speed up product development,These advantages have been paid attention to by many manufacturing companies。

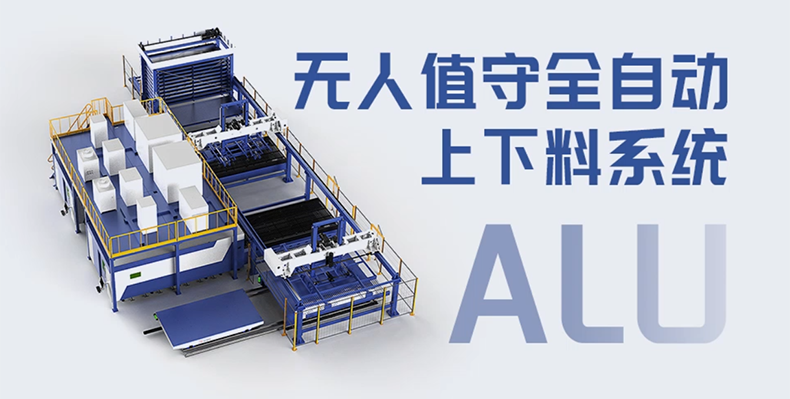

SLU series single machine loading and unloading、AS-S single-row storage material warehouse

Integrated CNC technology、Laser cutting、High-tech products integrating precision machinery

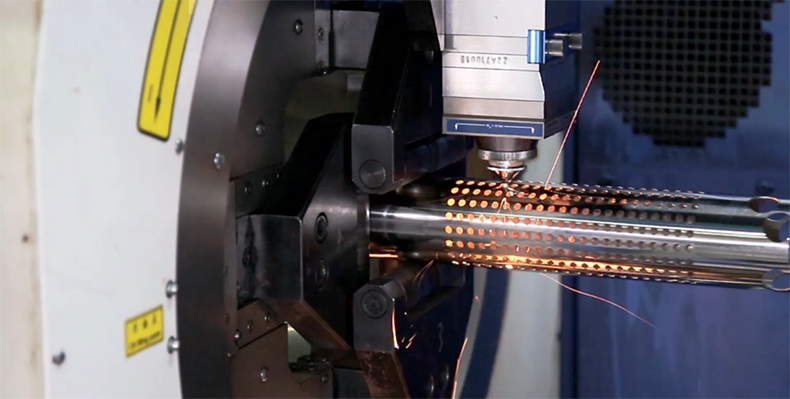

High single-machine machining efficiency、Completely dust-free、No stress、Bulbless,Industry-specific laser equipment with smooth and neat cutting edges,Can be applied to metal sheet processing。

Laser cutting machine new upgrade,High-quality price ratio,Strengthen efficiency,Smart production,Connectivity; Large-size workpieces - times of loading and forming