Laser cutting machine

Laser cutting machine can cut metal materials (carbon steel、Stainless steel、Titanium alloy、Aluminum) and non-metallic materials (acrylic、Glass、ceramics、Composite material)。Mainly used in automobile manufacturing、Aerospace、Sheet metal processing、Electronic equipment、Advertising and decoration industries。High cutting accuracy (tolerance ≤0.1mm)、Smooth incision without burrs、Characteristics of small heat-affected zones,Able to process complex special-shaped parts,Fast cutting speed and high flexibility,Automatic production can be realized through CNC system,Significantly improve material utilization and processing efficiency。

-

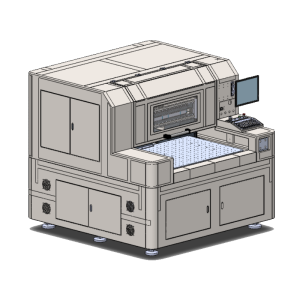

Laser cutting machine

CT-5050 laser cutting machine

1:Use high-performance lasers with imported high-speed scanning galvanometer、Field mirror,Focused spot fine、Little heat impact、Fine cuts、High cutting accuracy。 2:Adopt high-resolution CCD and lens,Achieve high-precision automatic positioning、Focus and other functions,Supports multiple visual positioning features,Like a cross、round、L-shaped right-angle side、Image feature points, etc.。 3:Adopt self-developed control software,With multi-plate cutting、Autozoom、Increase and shrinkage compensation、Multiple image parameter saving and automatic switching functions such as,Achieve high-precision machining。 4:The dust extraction system can eliminate all the cutting waste gas,Avoid hazards to operators and pollution to the environment。 5:The equipment adopts a high rigidity design、Machine tool base composed of natural marble and square structure plus shock absorber machine tool footglass,It can not only reduce inertial vibrations caused by the workbench start/stop and acceleration,It can also effectively prevent bed stress deformation caused by climate change temperature difference。Explore products -

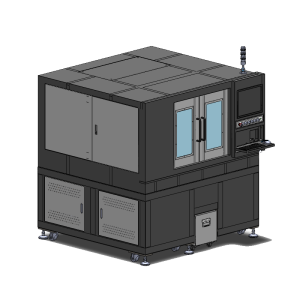

Laser cutting machine

CT-8080 laser cutting machine

1:Use high-performance lasers with imported high-speed scanning galvanometer、Field mirror,Focused spot fine、Little heat impact、Fine cuts、High cutting accuracy。 2:Adopt high-resolution CCD and lens,Achieve high-precision automatic positioning、Focus and other functions,Supports multiple visual positioning features,Like a cross、round、L-shaped right-angle side、Image feature points, etc.。 3:Adopt self-developed control software,With multi-plate cutting、Autozoom、Increase and shrinkage compensation、Multiple image parameter saving and automatic switching functions such as,Achieve high-precision machining。 4:The dust extraction system can eliminate all the cutting waste gas,Avoid hazards to operators and pollution to the environment。 5:The equipment adopts a high rigidity design、Machine tool base composed of natural marble and square structure plus shock absorber machine tool footglass,It can not only reduce inertial vibrations caused by the workbench start/stop and acceleration,It can also effectively prevent bed stress deformation caused by climate change temperature difference。Explore products -

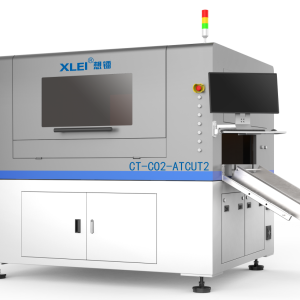

Laser cutting machine

CT-CO2-ATCUT2 laser cutting machine

1:Equipped with high power CO2 laser,Can meet high-speed cutting efficiency。 2:Online flight cutting,Marble linear motor platform,Meet fast cutting efficiency and effect。 3:Use a high-speed scanning galvanometer,X/Y workbench adopts a gantry structure,Marble pedestal,Flying light path design,High stability。 4:Fully automatic pulling and discharge,Meet the needs of fully automatic cutting reflective film。 5:The air suction system can eliminate all the cut exhaust gas,Avoid hazards to operators and pollution to the environment。Explore products -

Laser cutting machine

CT-DCM-6555激光切割机

Equipped with high power CO2 laser,Can meet high-speed cutting efficiency。 大理石高精度丝杆平台,Meet fast cutting efficiency and effect。 X/Y工作台采用动龙门结构,Marble pedestal,Flying light path design,High stability。 The air suction system can eliminate all the cut exhaust gas,Avoid hazards to operators and pollution to the environment。Explore products -

Laser cutting machine

CT-Glass-Cut2 激光切割机

采用皮秒激光结合贝塞尔切割头技术,崩边可控制在20微米以内,边缘光滑如镜,无需二次打磨。 最小切割精度达0.1mm,定位精度3微米,适用于超薄蓝宝石玻璃等高精度需求场景。 最高速度可达300毫米/秒,连续作业不间断,效率比传统水刀或CNC提升30%-50%。 整合切割、裂片、磨边工序,减少设备切换时间,良品率提高20%。 可切割厚度从0.1mm至45mm的玻璃,涵盖青玻、白玻、高硼硅、K9玻璃及蓝宝石等透明/有色材料。 此机型有效切割幅面达1200*800mm,满足大型玻璃加工需求。Explore products -

Laser cutting machine

CT-Glass-Cut3激光切割机

波长特性:绿光激光器在异形孔加工中表现优异,能量锁定更精准。 脉冲控制:通过多次扫描和脉冲间隔规避崩边风险。 加工速度:较传统工艺提升效率50%-100%,最快3秒完成单孔。 运动控制:直线电机与振镜系统实现高速打孔,双头旋转平台提升产能。 适应性:自动识别球面弧度,垂直聚焦确保曲面加工一致性。 非接触加工:Small heat-affected zone,避免传统钻孔的应力破裂风险。 加工工艺:支持圆孔、方孔、异形孔及阵列孔等多种形态编程控制,适应燃气灶面板、光伏组件、灯饰玻璃等多样化场景。Explore products -

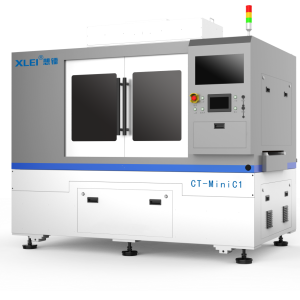

Laser cutting machine

CT-MiniC1 激光分板机

1:Adopt fiber laser,Good optical mode,Long life span,Simple maintenance。 2:Use special laser cutting head、Automatic follow system and special fixtures,Good cutting quality,Cutting thickness 0.5-2mm(Depends on material efficiency)。 3:Adopt high-precision linear motor platform and fully closed-loop grating detection and control system,Ensure the positioning and repeatability of the machine tool。 4:Online cutting board entry method is compatible with left in and right out、Right in and left out、Left in and left out、Right in and right out。 5:Stable performance of the whole machine,Ensure stable and efficient production of the machine,Equipped with industrial special industrial control computer,Automatic control of the entire process of computer software,Easy to operate。 6:Equipped with a high-pixel CCD camera,With automatic image recognition、High-precision image positioning kinetic energy,All kinds of marks can be captured(Target:Circle Cross),You can also grasp the edges and corners of the workpiece、Chamfer、Drilling, etc.。Explore products -

Laser cutting machine

CT-MiniC1-1 激光分板机

1:Adopt fiber laser,Good optical mode,Long life span,Simple maintenance。 2:Use special laser cutting head、Automatic follow system and special fixtures,Good cutting quality,Cutting thickness 0.5-2mm(Depends on material efficiency)。 3:Adopt high-precision linear motor platform and fully closed-loop grating detection and control system,Ensure the positioning and repeatability of the machine tool。 4:Online cutting board entry method is compatible with left in and right out、Right in and left out、Left in and left out、Right in and right out。 5:Stable performance of the whole machine,Ensure stable and efficient production of the machine,Equipped with industrial special industrial control computer,Automatic control of the entire process of computer software,Easy to operate。 6:Equipped with a high-pixel CCD camera,With automatic image recognition、High-precision image positioning kinetic energy,All kinds of marks can be captured(Target:Circle Cross),You can also grasp the edges and corners of the workpiece、Chamfer、Drilling, etc.。Explore products -

Laser cutting machine

CT-MiniC2 激光分板机

1:Adopt fiber laser,Good optical mode,Long life span,Simple maintenance。 2:Use special laser cutting head、Automatic follow system and special fixtures,Good cutting quality,Cutting thickness 0.5-2mm(Depends on material efficiency)。 3:Adopt high-precision linear motor platform and fully closed-loop grating detection and control system,Ensure the positioning and repeatability of the machine tool。 4:Online cutting board entry method is compatible with left in and right out、Right in and left out、Left in and left out、Right in and right out。 5:Stable performance of the whole machine,Ensure stable and efficient production of the machine,Equipped with industrial special industrial control computer,Automatic control of the entire process of computer software,Easy to operate。 6:Equipped with a high-pixel CCD camera,With automatic image recognition、High-precision image positioning kinetic energy,All kinds of marks can be captured(Target:Circle Cross),You can also grasp the edges and corners of the workpiece、Chamfer、Drilling, etc.。Explore products