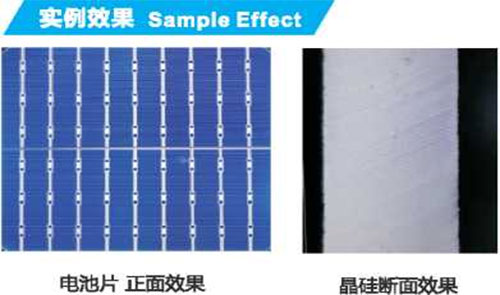

Half-piece is one of the most effective ways for photovoltaic modules to increase power by dividing the entire cell into half-film,Reduce the string current,This reduces the power loss of the series resistor,In order to achieve the effect of increasing component power,According to the current mass production data of first-line photovoltaic module factories, it is shown,The power of its half-piece component is increased by 6~7W,Remarkable effect。

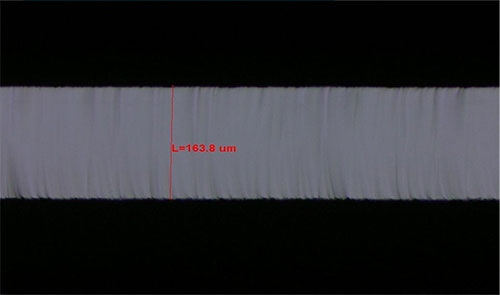

The core principle of lossless laser cutting is laser thermal stress control fracture technology,Local heating of the material with laser,A temperature gradient is generated on the surface of the material,This induces heat stress generation,Induce stable breakage of the material by appropriate control of thermal stress,Lossless laser cutting can achieve low temperature machining,Avoid ablation damage from solar cells。

Features:

Main components:Various lasers available,High onboard strength and optimization of cutting surface;Independent intellectual property rights,Several core patents。

No laser thermal damage on the battery section,No laser heat influence on the surface;

Good mechanical properties,High conversion efficiency;Maximum capacity ≥7200P/H,Multiple configurations available;

Widely compatible with mainstream and new crystalline silicon battery products。

Example effects:

Application areas:

Fully automatic laser slashing machine is used for the automated production of high-efficiency photovoltaic modules。The scribing assembly reduces the string current,Reduce resistance loss and improve output power of photovoltaic modules。

Lossless laser slashing machine for scribing process in high-efficiency photovoltaic module production,Replace conventional laser slashing machines,Completely solve the inevitable thermal damage of battery cells in conventional laser slashers。