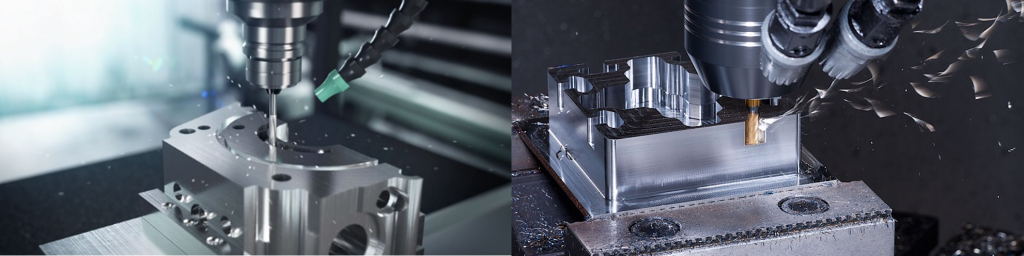

Metal cutting is an important manufacturing process,The metal cutting process is when the tool cuts off excess metal from the workpiece to be processed.,And while controlling productivity and cost,Give the workpiece geometric accuracy to meet design and process requirements、Dimensional accuracy and surface quality。

The cutting process of metal is performed by machine tools or hand-held tools.,The main method is car、Milling、plane、grind、Diamond、Boring、Gear machining、Score、saw、file、shave、research、Reaming hole、Thread tap、Thread set, etc.。

Metal cutting is one of the commonly used metal processing technologies in manufacturing,widelyApplied in various fields,Such as automobile manufacturing、Aerospace、Machinery manufacturing、Mold manufacturing, etc.:

Automobile manufacturing:Metal cutting technology plays an important role in automobile manufacturing。By placing engine parts、Cutting and processing of body structure parts, etc.,Ensure the accuracy and quality requirements of parts,Improve vehicle performance and safety。

3C&5G:Metal housings that can be used to manufacture electronic equipment、Radiator and other components,To provide good precision、Insulation and heat dissipation performance。

Machinery manufacturing:Metal cutting technology is one of the most commonly used processing technologies in mechanical manufacturing。Turning metal workpieces、Milling、Drilling and other cutting processing,All kinds of mechanical parts can be manufactured,As axis、gear、Threads, etc.。

Mold manufacturing:By cutting the mold material,Can manufacture molds of various complex shapes,For injection molding、Die casting and other industries。

With the continuous advancement of technology,The strategic position of industrial master machines is becoming increasingly prominent,Metal cutting machine tools are also constantly iterating and upgrading,For the high-quality development of advanced manufacturing industry,Provide strong technical and equipment support。